It’s been three years since the Rana Plaza factory in Bangladesh collapsed

What changes have been made to the industry since?

On Wednesday 24th of April, 2013, over 3000 workers were sent to work in the unsafe, eight story factory Rana Plaza, despite cracks being discovered in the building’s walls the previous day. The building collapsed, killing 1,134 people and injuring 2,500.

They were working 10 hour days and 6 day weeks on below the living wage, producing garments for a variety of international companies including the likes of Asda and Primark.

The aftermath

What’s changed since then?

The biggest change sparked by the disaster was the signing of an agreement by over 150 brands including Adidas, Primark, Arcadia Group (the company that owns Toshop and Miss Selfridge) and New Look. The agreement ensures the improvement of safety in Bangladesh’s garment factories, covering around half of Bangladesh’s 4 million garment workers. It resulted in three quarters of Bangladesh’s 3,508 garment factories going through safety assessments, and over 35 being shut down.

10% of the worldwide fashion industry have since committed to get rid of toxic chemicals by 2020 and over 160 brands have signed a pledge against child and forced labour in Uzbekistan.

In 2012, there were 122 unions in Bangladesh’s garment industry, representing less than 3% of workers, but the Rana Plaza collapse sparked a 20% increase in the number of unions and a rise in the number of garment workers joining them, and there are now over 400 unions. The Bangladeshi government also increased the minimum wage by 77%.

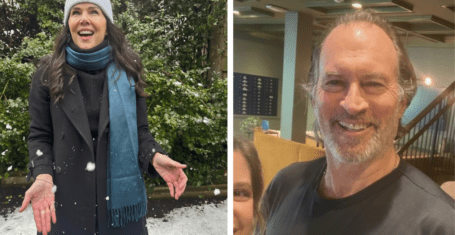

The ‘Fashion Revolution’ campaign was founded last year by designers Cary Somers and Orsola de Castro as a result of Rana Plaza. It got massive social media support, especially for the hashtag #haulternatives, where vloggers did YouTube ‘hauls’ using vintage finds and purchases from charity shops. This year it will include a campaign with the hashtag #whomademyclothes.

‘Child Labor Free’ has created a new system of labelling clothes to certify them as child labour free. Brands that apply for accreditation have to give details about their manufacturing and sourcing, and solid evidence that they don’t use children.

Major companies in the UK now have to give detailed reports as to how they are preventing slavery and trafficking in their production lines under the Modern Slavery Act.

What still needs to change?

While the safety of workers may have improved, largely their standard of life and worker’s rights has not. Garment exports alone, mainly to Europe and the US, from Bangladesh provide the country with an annual income of about $25 billion, and while the global average wage for garments workers is just £2 a day, Bangladesh has one of the lowest in the world at the equivalent of £45 a month.

The reforms that have taken place since Rana Plaza have been largely centered on Bangladesh, and have ignored the pressing problems of garment labour in other countries.

Worldwide child labour still denies over 170 million children the right to proper education, happiness, and health, and one cotton famer commits suicide every 30 minutes largely due to living a life of poverty, while in comparison the fashion industry makes an annual turnover of £2 trillion, with over £100 million worth of clothing ending up in UK landfill each year.

What have our favourite shops done since to make the production of ‘fast fashion’ more ethical and sustainable?

Primark said that it would continue to pay the salaries to those affected by Rana Plaza for three more months, but it turned out that only those who could give DNA evidence of a family member’s death were entitled to this payment.

However, they were the first company to acknowledge production of their garments in Rana Plaza, send aid there, and were among the first brands to sign the accord.

Who made all of these?

They also score a top rating from Ethical Consumer for their supply chain management, as does Arcadia (Topshop and Miss Selfridge) and New Look, whereas River Island and Amazon got the worst rating.

Over half of H&M’s main suppliers in Bangladesh still haven’t installed basic fire safety measures and 13% of those suppliers have yet to take the basic step of removing locks from key fire exit doors. However H&M is one of just a handful to actually release a list of some of its suppliers in Bangladesh, thus allowing charities to check these out. They also launched World Recycle Week on 18 April 2014, run their own clothes recycling programme and produce organic clothes, as well as receiving a top rating from Ethical Consumer for their supply chain management.

Both Zara and H&M have begun to pay wages above the legal minimum at the final stage of production, though this doesn’t apply to the textile workers or farmers before them in the chain.

Failing to take full responsibility for the human cost of the clothes we wear is something we’re all guilty of, and these lists are by no means extensive, but the aim of this article was to remind you of what happened three years ago, to try and inspire you to take responsibility for what and where you buy, and mostly, to try and give a snapshot of what has and hasn’t changed in the industry, as the huge amounts of often inaccurate and conflicting information everywhere on the internet and even on brands websites is enough to put anyone of trying shop ethically.